Osmotic Shock System

The operating life of ion exchange resins depends on several factors. Degradation of resin can be attributed to mechanical, thermal or osmotic shock, temperature, dissolved oxygen, and chemical oxidation due to attack of chemical like chlorine.

When resins are in actual use, they are exposed to low & high concentrations of electrolytes. This kind of alternate exposure causes swelling & shrinking of particles and subsequently it results in cracking and reducing particle size. Life of resins thus reduces due to alternate absorption and regeneration.

To get an idea about the performance of the resins with respect to their strength against Osmotic Shock it is essential to simulate the conditions so that in a short time under specified method the resin columns are subjected to acid wash, alkali wash, D.M. Water wash etc. The resins under test are then checked by regular methods. The number of cycles and the wash conditions will help you to estimate the life of resins.

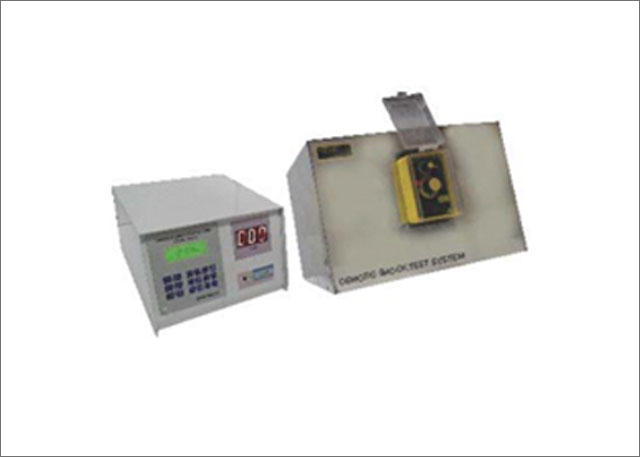

The “Spectralab Osmotic Shock Test System” is programmable by which you can set your method i.e. flow of acid, alkali, D.M. Water, the direction of flow ( up or down ) & time duration of flow. It gives digital counts of cycles & is displayed on large display and switches off automatically after predetermined cycles. The system is microcontroller based. All the valves & tubing’s are chemical resistant. You can connect three columns at a time. The flow is controller by precision dosing pump.